Petroleum sieve mesh

Petroleum sieve mesh

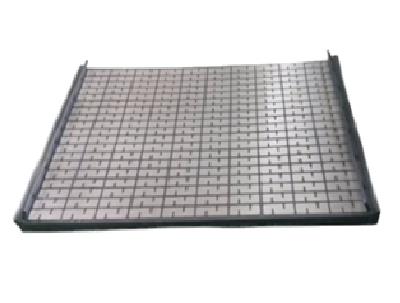

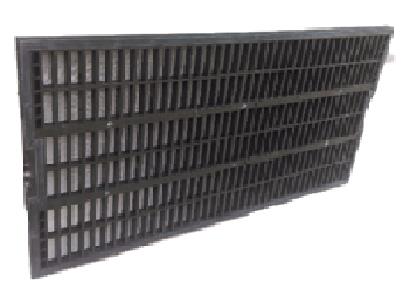

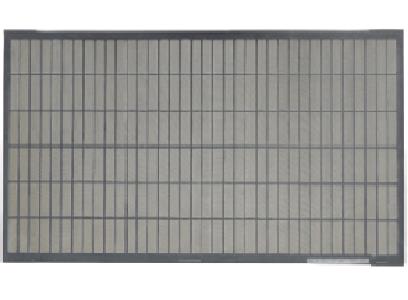

The Motec steel frame screen improves durability, is lighter, easier to maintain, extends the service life of the screen, and is more flexible to operate. Economy: The HHBV300 screen has a higher effective utilization rate in mud treatment compared to domestic equivalent screens. After testing, the HHBV300 has a failure rate of less than 5%

- Email:Sales@machtec.cn

- Telephone:+86 22 60978800

Motec always maintains the tradition of precision craftsmanship, using high-quality raw materials and advanced production processes and equipment, strictly controlling quality, and producing according to API RP13C standards.

At present, a production capacity of 80000 pieces of various types of screen mesh has been formed annually. The product varieties include composite frame screen mesh, flat screen mesh, and wave screen mesh, with hundreds of specifications ranging from 12 mesh to 325 mesh.

Technical parameters:

Mesh model | Scope of Contents | Size (length)×Wide) | Adapt to the brand and model of vibrating screen | Weight(kg) |

HHD500 | 16-325 | 695×1050mm | DERRICK FLC 500 | 9 |

HHSM | 16-325 | 585×1165mm | SWACO Foundation MONGOOSE | 11 |

HHBB-50 | 16-325 | 635×1253mm | BRAND COBRA | 13 |

HHBV300 | 16-325 | 889×686mm | BRAND VSM300 | 11 |

HHKPT28 | 16-325 | 720×1250mm | KEMTRON KTL48 Series | 16 |

HHSF300 | 16-325 | 712×1181mm | SF300 | 14 |

Features and advantages:

E High strength screen frame with supporting steel bars inside to enhance fluid impact resistance and extend the service life of the screen;

E Multiple independent small cell grid backboards to prevent the spread of minor damage. At the same time, equipped with repair tools, saving time and costs;

E The unique multi-layer mesh design effectively improves the efficiency of the screen mesh;

E The sieve has better corrosion resistance and is lighter in weight.

If you have any questions or support, please fill in the following information and we will reply to you as soon as possible!!