Screw drilling tool

Screw drilling tool

Screw drilling tool is a downhole power drilling tool powered by drilling fluid, and its core power component is a positive displacement motor. Hydraulic energy is converted into mechanical energy, and the rotor drives the spindle and drill bit to rotate, allowing the drill bit to drill and achieve the purpose of drilling. This drilling tool is easy to operate and has reliable performance. Drilling tools are made of oil-based mud, emulsified mud, and clay mud

- Email:Sales@machtec.cn

- Telephone:+86 22 60978800

Screw drilling tool is a downhole power drilling tool powered by drilling fluid, and its core power component is a positive displacement motor. Hydraulic energy is converted into mechanical energy, and the rotor drives the spindle and drill bit to rotate, allowing the drill bit to drill and achieve the purpose of drilling. This drilling tool is easy to operate and has reliable performance. Drilling tools use various drilling fluids such as oil-based mud, emulsified mud, and clay mud as power fluids, with strong adaptability, and can be used for drilling special wells such as horizontal wells and cluster wells, greatly improving drilling speed and economic benefits. At present, in addition to the more common straight screw drilling tools, Motech can also provide the following forms of screw drilling tools:

1. Adjustable angle bending screw drilling tool: To improve the requirements of different inclination angles for bending screw drilling tools, the bending angle of the screw drilling tool can be adjusted on the well as needed. The length of the whole machine is shorter, and the inclination can reach>1 ·/m

2. Equal wall thickness screw drilling tool: Equal wall thickness screw is a new type of screw drilling tool. It has shown greater advantages than conventional screw drilling tools in applications such as deep wells, large displacement, and short radius horizontal wells.

3. Saturated salt water mud resistant screw drilling tool: In order to enable the entire screw drilling tool to work for a long time in a saturated salt water mud environment, a special drilling tool coating is used, which is more corrosion-resistant and wear-resistant.

4. High temperature type screw drilling tool: In order to improve the high temperature resistance of the stator rubber of the screw drilling tool and meet the drilling needs of high temperature gradient areas and deep and ultra deep wells under high temperature conditions, high-quality high-temperature resistant rubber is used to manufacture the motor stator, which can increase the temperature resistance of the motor to 150 degrees Celsius Above C.

5. Sealed transmission shaft screw drilling tool: Replace the ordinary mud lubricated transmission shaft with an oil lubricated sealed transmission shaft, improve the working environment of thrust bearings and radial bearings, and extend the overall service life of the screw drilling tool.

model | Outer diameter,mm | Valve ratio | series | Drilling tool length | Effective length of stator | The maximum diameter of the transmission shaft assembly,mm | Lower arm length,mm | Upper thread | Lower thread |

5LZ43×7.0 M-4 | 43 | 5:6 | 4 | 1707 | 820 | 43 | \ | 1AMMT | 1AMMT |

5LZ45×7.0 M-3 | 45 | 5:6 | 3 | 1927 | 1040 | 45 | \ | 1AMMT | 1AMMT |

5LZ54×7.0 M-3 | 54 | 5:6 | 3 | 2119 | 1130 | 54 | \ | 1REG | 1REG |

7LZ54×7.0 M-4 | 54 | 7:8 | 4 | 2699 | 1710 | 54 | \ | 1REG | 1REG |

5LZ60×7.0 M-3 | 60 | 5:6 | 3 | 3745 | 1850 | 60 | \ | 1REG | 1REG |

5LZ73×7.0 M-7 | 73 | 5:6 | 7 | 4717 | 2850 | 73 | 813 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ79×7.0 M-4 | 79 | 5:6 | 4 | 4355 | 2450 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ79×7.0 M-5 | 79 | 5:6 | 5 | 4855 | 3000 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

7LZ79×7.0 M-4 | 79 | 7:8 | 4 | 3525 | 1650 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

7LZ79×7.0 M-4 | 79 | 7:8 | 4 | 3525 | 1650 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ89×7.0 M-4 | 89 | 5:6 | 4 | 4759 | 2450 | 89 | 1103 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

4LZ95×7.0 M-5 | 95 | 4:5 | 5 | 5619 | 3050 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-3 | 95 | 5:6 | 3 | 4419 | 1850 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-5 | 95 | 5:6 | 5 | 5619 | 3050 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-7 | 95 | 5:6 | 7 | 5979 | 3410 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-3 | 95 | 7:8 | 3 | 4419 | 1850 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-10.1 | 95 | 7:8 | 10.1 | 7869 | 5300 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-6.7 | 95 | 7:8 | 6.7 | 6749 | 4180 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

9LZ95×7.0 M-4 | 95 | 9:10 | 4 | 5019 | 2450 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ105×7.0 M-4 | 105 | 5:6 | 4 | 4898 | 2450 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

5LZ105×7.0 M-10.1 | 105 | 5:6 | 10.1 | 7768 | 5320 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

7LZ105×7.0-6 | 105 | 7:8 | 6 | 6678 | 4230 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

9LZ105×7.0 M-6 | 105 | 9:10 | 6 | 6458 | 4010 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

7LZ108×7.0 M-6 | 108 | 7:8 | 6 | 6818 | 4370 | 108 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

5LZ120×7.0 M-5 | 120 | 5:6 | 5 | 7192 | 4540 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

5LZ120×7.0 M-6 | 120 | 5:6 | 6 | 7892 | 5240 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-4 | 120 | 7:8 | 4 | 6282 | 3630 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-6.5 | 120 | 7:8 | 6.5 | 8522 | 5870 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-7 | 120 | 7:8 | 7 | 7092 | 4420 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-8 | 120 | 7:8 | 8 | 7692 | 5040 | 120 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

4LZ127×7.0 M-6 | 127 | 4:5 | 6 | 7052 | 4400 | 127 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

4LZ127×7.0 M-5 | 127 | 4:5 | 5 | 6332 | 3680 | 127 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

5LZ127×7.0 M-5 | 127 | 5:6 | 5 | 7022 | 4370 | 127 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ127×7.0 M-4 | 127 | 7:8 | 4 | 6282 | 3630 | 127 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ127×7.0 M-7 | 127 | 7:8 | 7 | 7092 | 4420 | 127 | 1223 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ135×7.0 M-5 | 135 | 7:8 | 5 | 7775 | 4450 | 135 | 1280 | NC-38(Z-102) | 3 1/2REG (3-88) |

7LZ140×7.0 M-5 | 140 | 7:8 | 5 | 7425 | 4100 | 140 | 1495 | NC-50 (Z-133) | 4 1/2REG (3-117) |

5LZ159×7.0 M-5 | 159 | 5:6 | 5 | 8067 | 4250 | 159 | 1939 | NC-50 (Z-133) | 4 1/2REG (3-117) |

7LZ159×7.0 M-3 | 159 | 7:8 | 3 | 7227 | 3410 | 159 | 1939 | NC-50 (Z-133) | 4 1/2REG (3-117) |

4LZ165×7.0 M-7 | 165 | 4:5 | 7 | 9257 | 5440 | 165 | 1872 | NC-50 (Z-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-4 | 165 | 5:6 | 4 | 7227 | 3410 | 165 | 1872 | NC-50 (Z-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-5 | 165 | 5:6 | 5 | 8067 | 4250 | 165 | 1872 | NC-50 (Z-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-6 | 165 | 5:6 | 6 | 8907 | 5090 | 165 | 1872 | NC-50 (Z-133) | 4 1/2REG (3-117) |

7LZ165×7.0 M-5 | 165 | 7:8 | 5 | 9617 | 5800 | 165 | 1872 | NC-50 (Z-133) | 4 1/2REG (3-117) |

4LZ172×7.0 M-7 | 172 | 4:5 | 7 | 9257 | 5440 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-4 | 172 | 5:6 | 4 | 7227 | 3410 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-5 | 172 | 5:6 | 5 | 8067 | 4250 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-6 | 172 | 5:6 | 6 | 8907 | 5090 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

6LZ172×7.0 M-6.5 | 172 | 6:7 | 6.5 | 8417 | 4600 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5 | 172 | 7:8 | 5 | 8437 | 4620 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5.5 | 172 | 7:8 | 5.5 | 8897 | 5080 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-6 | 172 | 7:8 | 6 | 9347 | 5530 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5.7 | 172 | 7:8 | 5.7 | 10027 | 6210 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-7.5 | 172 | 7:8 | 7.5 | 10167 | 6350 | 172 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

3LZ178×7.0 M-6 | 178 | 3:4 | 6 | 8832 | 5090 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

4LZ178×7.0 M-7 | 178 | 4:5 | 7 | 9172 | 5440 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-4 | 178 | 5:6 | 4 | 7152 | 3410 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-5 | 178 | 5:6 | 5 | 7992 | 4250 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-6 | 178 | 5:6 | 6 | 8832 | 5090 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-7 | 178 | 5:6 | 7 | 10292 | 6560 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

6LZ178×7.0 M-6.5 | 178 | 6:7 | 6.5 | 8962 | 5230 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5 | 178 | 7:8 | 5 | 8362 | 4620 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5.5 | 178 | 7:8 | 5.5 | 8897 | 5080 | 178 | 1867 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5.7 | 178 | 7:8 | 5.7 | 9952 | 6210 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6B | 178 | 7:8 | 6 | 9262 | 5530 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6 I | 178 | 7:8 | 6 | 8932 | 5090 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6 | 178 | 7:8 | 6 | 8932 | 5200 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

F7LZ178×7.0 M-6 | 178 | 7:8 | 6 | 8932 | 5200 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-7 | 178 | 7:8 | 7 | 8992 | 5260 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-7.5 | 178 | 7:8 | 7.5 | 10092 | 6350 | 178 | 1923 | 5 1/2FH (Z-147) | 4 1/2REG (3-117) |

7LZ185×7.0 M-7 | 185 | 7:8 | 7 | 9672 | 5930 | 185 | 1923 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

3LZ197×7.0 M-7 | 197 | 3:4 | 7 | 10063 | 5930 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

4LZ197×7.0 M-6 | 197 | 4:5 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

5LZ197×7.0 M-4 | 197 | 5:6 | 4 | 7543 | 3410 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

5LZ197×7.0 M-5 | 197 | 5:6 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

5LZ197×7.0 M-6 | 197 | 5:6 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

6LZ197×7.0 M-5 | 197 | 6:7 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

6LZ197×7.0 M-6 | 197 | 6:7 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

9LZ197×7.0 M-4 | 197 | 9:10 | 4 | 7543 | 3410 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

7LZ197×7.0 M-5 | 197 | 7:8 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

4LZ203×7.0 M-6 | 203 | 4:5 | 6 | 9397 | 5090 | 203 | 2192 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

5LZ203×7.0 M-5 | 203 | 5:6 | 5 | 8857 | 4550 | 203 | 2192 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

5LZ203×7.0 M-6 | 203 | 5:6 | 6 | 9757 | 5450 | 203 | 2192 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

7LZ203×7.0 M-5 | 203 | 7:8 | 5 | 8557 | 4250 | 203 | 2192 | 5 1/2FH (Z-147) | 6 5/8REG (Z-152) |

3LZ210×7.0 M-7 | 210 | 3:4 | 7 | 10364 | 5930 | 210 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

7LZ210×7.0 M-5 | 210 | 7:8 | 5 | 8704 | 4250 | 210 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

7LZ210×7.0 M-7 | 210 | 7:8 | 7 | 10104 | 5650 | 210 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

5LZ210×7.0 M-5 | 210 | 5:6 | 7 | 10104 | 5650 | 210 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

5LZ216×7.0 M-6 | 216 | 5:6 | 6 | 9544 | 5090 | 216 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

7LZ216×7.0 M-5 | 216 | 7:8 | 5 | 8704 | 4250 | 216 | 2243 | 6 5/8REG (Z-152) | 6 5/8REG (Z-152) |

5LZ228×7.0 M-6 | 228 | 5:6 | 6 | 9544 | 5090 | 228 | 2243 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) |

3LZ244×7.0 M-4 | 244 | 3:4 | 4 | 10633 | 6000 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152)/ |

3LZ244×7.0 M-6 | 244 | 3:4 | 6 | 10783 | 6210 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

F3LZ244×7.0 M-6 | 244 | 3:4 | 6 | 10783 | 6210 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

5LZ244×7.0 M-4 | 244 | 5:6 | 4 | 8663 | 4080 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

5LZ244×7.0 M-5 | 244 | 5:6 | 5 | 9673 | 5090 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

5LZ244×7.0 M-6 | 244 | 5:6 | 6 | 10683 | 6100 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

C5LZ244×7.0 M-4 | 244 | 5:6 | 4 | 9673 | 5090 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

7LZ244×7.0 M-4 | 244 | 7:8 | 4 | 8663 | 4080 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

C7LZ244×7.0 M-4 | 244 | 7:8 | 4 | 9693 | 5110 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

7LZ244×7.0 M-5 | 244 | 7:8 | 5 | 10113 | 5530 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

7LZ244×7.0 M-5.7 | 244 | 7:8 | 5.7 | 10383 | 5800 | 244 | 2371 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

3LZ286×7.0 M-4 | 286 | 3:4 | 4 | 10240 | 5170 | 286 | 2600 | 6 5/8REG (Z-152)/ | 6 5/8REG (Z-152) / |

Features and advantages:

1、 Bypass valve

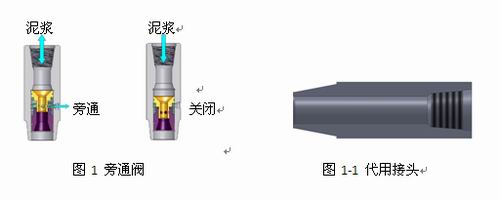

It has two positions: bypass and close (as shown in Figure 1). During the drilling operation, it is in the bypass position, which allows the mud in the drill string to circulate around the non working motor and enter the annulus, so that the mud does not overflow on the wellhead during drilling. When the mud flow rate and pressure reach the standard set values, the valve core moves downward and closes the bypass valve hole. At this time, the mud flows through the motor, converting pressure energy into mechanical energy. When the mud flow rate is too low or the pump stops, the pressure generated is not enough to overcome the spring force and static friction force. The spring lifts the valve core and the bypass valve hole is in the open position again. In general, substitute joints are often used for deep wells, highly inclined wells, horizontal wells, and when using hollow rotors. (As shown in Figure 1-1)

2、 Motor assembly

It consists of a stator and a rotor. The stator is made by injecting rubber lining on the inner wall of the steel pipe. The rubber inner hole is a spiral with certain geometric parameters. The rotor is a screw with a chrome plated hard layer.

The motor assembly produced by our company has the following advantages:

1. The stator and rotor materials are made of 42CrMo integral quenching and tempering, with hardness reaching HB285-341 and HB260-300 respectively, and the mechanical properties of the materials have been greatly improved.

2. The line type can be optimized and designed according to customer requirements and usage, which can significantly improve the overall efficiency of the screw.

3. Various types of motors suitable for on-site industrial and mining conditions can be provided.

Divided by working temperature:

(1) Normal temperature stator: rated temperature is 95 ℃, with a higher temperature of 120 ℃.

(2) High temperature stator: rated temperature of 105 ℃, higher temperature of 150 ℃.

(3) Ultra high temperature stator: rated temperature of 165 ℃, higher temperature of 180 ℃.

Classified by mud type:

Water based mud.

Oil based mud.

Highly saturated saltwater mud.

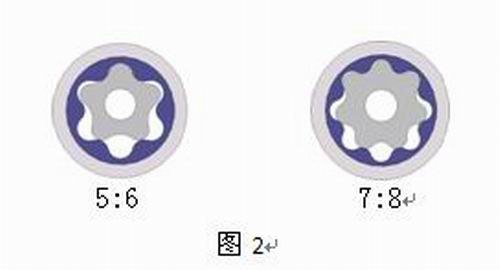

4. According to customer requirements, hollow rotors can be produced and processed, which can increase the water horsepower of the drill bit and the upward and backward speed of the mud. (Figure 2)

5. The interference fit size of the rotor and stator can be recommended according to different customer operating conditions, which can effectively improve the service life and work efficiency of the motor.

6. The company has successfully developed and researched equal wall thickness screw drilling tools, which have the advantages of: ① high single-stage pressure, improving system efficiency; ② Good heat dissipation characteristics improve the working life of the stator; ③ Uniform rubber expansion improves the stability of stator operation; ④ Increased the bonding area between rubber and metal, enhancing the bonding strength. The wider adaptability, more optimized structure, and lighter overall weight can effectively improve the working environment of screw drilling tools and increase their service life. (Figure 2-1)

7. According to the on-site working conditions, rotors under different media can be provided.

① Conventional rotor, chrome plated surface, suitable for water-based mud and oil-based mud;

② Tungsten carbide rotor, surface coated with tungsten carbide, suitable for saturated saltwater slurry;

③ Ceramic rotor, surface coated with ceramic, suitable for saturated saltwater slurry;

8. The company has a complete set of imported rubber testing equipment and has established a sound inspection process and methods, effectively ensuring the consistency between design, development, and production.

3、 Universal shaft:

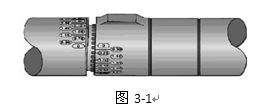

The function of the universal joint is to convert the planetary motion of the motor into the fixed axis motion of the transmission shaft, and transmit the torque and speed generated by the motor to the transmission shaft and the drill bit. The Motec drilling tool adopts advanced ball drive universal shafts and roller drive universal shafts, which are connected by ball drive and roller drive respectively. The moving parts are sealed with rubber sleeves to isolate the drilling fluid, and special surface treatment is carried out on the working face to improve its surface hardness and high temperature resistance; The working life is correspondingly extended. (as shown in Figure 3).

After using the drilling tool, it should be immediately disassembled and the universal joint should be inspected. If the wear exceeds the maintenance standard, the relevant vulnerable parts should be replaced in a timely manner, otherwise the drilling tool may not work properly due to excessive use of the universal joint.

The adjustable universal joint angle can reach 0-4 °, and a larger adjustable range of adjustable housing can be customized according to customer requirements to meet engineering requirements. (Figure 3-1)

4、 Transmission shaft assembly

The function of the drive shaft is to transmit the rotational power of the motor to the drill bit, while bearing the axial and radial loads generated by the drilling pressure. Our company's drilling tool transmission shaft assembly has two structures:

(1) The pressure drop of the drill bit water hole is 7.0 MPa, and the transmission shaft assembly is composed of hard alloy radial bearings and a set of thrust bearings in the middle.

(2) The pressure drop of the drill bit water hole is 14.0MPa, and it adopts hard alloy radial bearings and diamond composite disc (PDC) flat thrust bearings, which have longer service life and higher load-bearing capacity.

The transmission shaft produced by our company is forged from 40CrNiMoA high-performance alloy steel and then processed into shape, effectively improving reliability and service life.

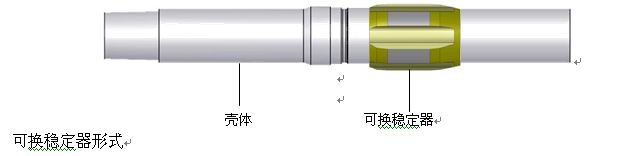

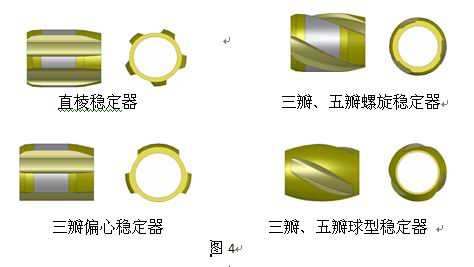

In order to meet the needs of drilling, our company's transmission shaft assembly is equipped with different types of stabilizers on the outer shell, including fixed and replaceable ones. The stabilizer's stabilizer bar has various forms, and users can choose to use it according to the needs of drilling technology. (Figure 4)

5、 Whole machine

The whole machine adopts three-level anti drop, making it safer and more reliable to use.

If you have any questions or support, please fill in the following information and we will reply to you as soon as possible!!