Solid control series

Solid control series

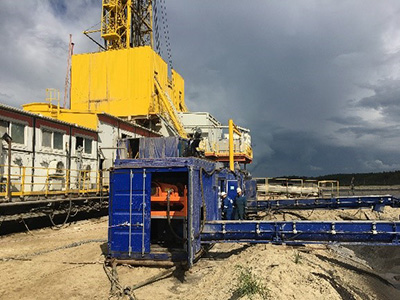

The drilling fluid waste treatment system is an equipment for further separation and treatment of various rock cuttings and waste mud generated during petroleum drilling and production operations. This equipment can process drilling fluid waste processed by the solid control system, reducing the oil and water content of the drilling cuttings to meet the requirements of discharge and secondary treatment; The processed drilling fluid can be further separated and processed to stabilize the liquid phase performance and return it to the solid control system for secondary injection and utilization.

- Email:Sales@machtec.cn

- Telephone:+86 22 60978800

The drilling fluid waste treatment system is an equipment for further separation and treatment of various rock cuttings and waste mud generated during petroleum drilling and production operations. This equipment can process drilling fluid waste processed by the solid control system, reducing the oil and water content of the drilling cuttings to meet the requirements of discharge and secondary treatment; The processed drilling fluid can be further separated and processed to stabilize the liquid phase performance and return it to the solid control system for secondary injection and utilization.

Technical Parameter | Vertical spin dryer module | Horizontal centrifuge module |

Processing capacity | 30-50 t/h | 30m³/h |

drying efficiency | OOC≤5% | - |

Power (total) | 120kw | 100kw |

Electrical components | Schneider, Siemens | |

Explosion proof standard | ExdIIBT4/IECEX/ATEX | |

Power supply system | AC380V,50Hz | |

weight | 13000kg | 11000kg |

External dimensions | 6258x2550x3072mm | 6258x2550x2925mm |

Features and advantages:

1Adopting a dual module design of a spin dryer module and a centrifuge module, the dual modules can be combined for processing, and each module can also work separately as needed.

2Each module is connected to the drilling rig's solid control system and between modules using conveyors, which can adapt to the layout requirements of different well sites.

3The overall production efficiency is high, and it can work continuously while drilling.

4Adopting container mode, the structure is compact, convenient for installation, movement, and transportation.

5The module is insulated as a whole and can work normally in low temperature environments.

If you have any questions or support, please fill in the following information and we will reply to you as soon as possible!!